Flanges play an important role in engineering and construction, providing stability, ease of attachment, and reinforcement in various applications. They are used to connect pipes, valves, and equipment, ensuring the efficient operation of systems. One specific type of flange, the AWWA (American Water Works Association) flange, serves a vital function in water utility systems and other light-duty applications.

Image source: Texasflange.com

Image source: Texasflange.com

Common Flange Types and Characteristics

Flanges come in various types, each designed for specific purposes:

- Weld Neck Flanges: These are butt-welded onto pipe ends, suitable for high-temperature and high-pressure applications.

- Threaded Flanges: Featuring an internal thread, these allow pipes to be screwed in, although they aren’t ideal for high-pressure and high-temperature scenarios.

- Socket-Welded Flanges: Designed for small-diameter pipes and low-pressure situations, these have a plain hole with a shoulder for welding.

- Slip-On Flanges: Similar to socket-welded flanges but without the shoulder, they are secured with fillet welds.

- Lapped Flanges: Consisting of two parts, they allow disassembly in confined spaces and are useful for specific connection needs.

- Blind Flanges: These serve as blanking plates to isolate sections of piping or terminate pipes.

Flange Standards

Flanges adhere to specific standards that define dimensions, surface finish, facing type, marking, material, and technical specifications. Notable standards include those established by institutions like ASME, AWWA, JIS, ISO, and CEN. This article focuses on AWWA and JIS standards for flanges.

AWWA: The American Water Works Association

Image source: Texasflange.com

AWWA is an international nonprofit organization dedicated to managing water effectively and ensuring water quality. With a membership of over 51,000, it plays a significant role in water supply and wastewater treatment. AWWA standards are particularly relevant in the water utility sector.

AWWA Flanges

AWWA flanges are designed for low-pressure applications, typically 300 psi or less. They find use in a variety of assemblies where the medium isn’t corrosive and temperatures are ambient. Common applications include waterworks, slurry transport, wastewater management, and low-pressure plant piping.

AWWA Certified Flange Types

Unlike ANSI and ASME standards, AWWA Flange Standards focus specifically on a limited range of flange types, including:

- Slip-on Ring and Hub Type Flanges (fitted over a pipe)

- Blind Flanges (used to seal or close pipes or vessels)

- Threaded Iron Flanges (fitted to externally threaded pipes)

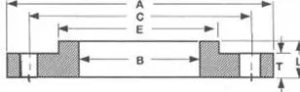

AWWA C207 Steel Flanges

AWWA C207 is a significant standard for AWWA steel flanges. These flanges are often made from mild carbon steel or stainless steel and are commonly of the ring slip-on or blind disc style. They are sealed with rubber gaskets and are becoming more popular in structural steel projects that require filling gaps between existing flanges.

Image source: Texasflange.com

Image source: Texasflange.com

Industries and Applications

AWWA Standard Flanges are designed for light-duty applications, typically below 300 psi. The most common pressure range is AWWA Class D, with ratings of 175 psi for sizes under 12 inches and 150 psi for larger sizes. They are used in waterworks, slurry transport, wastewater management, and plant piping.

Image source: Texasflange.com

FAQs About AWWA Flanges

What is the primary purpose of AWWA flanges?

AWWA flanges serve as critical components in water utility systems, connecting pipes, valves, and equipment.

What are the pressure ratings available for AWWA flanges?

AWWA flanges come in various pressure ratings, ranging from Class B (86 psi) to Class F (300 psi), catering to different water utility conditions.

How are AWWA flanges typically attached to steel pipes and equipment?

AWWA flanges are often attached using welding, ensuring a secure and leak-free connection.

What materials are commonly used to manufacture AWWA flanges?

AWWA flanges can be made from materials like seamless forgings, single-piece plate cutting, welded bar rings, or segmented and welded plates, meeting specific material requirements.

Are AWWA flanges suitable for wastewater applications?

Yes, AWWA flanges find applications in both wastewater management and water treatment, as well as various light-duty scenarios.

What are the key differences between ring-type and hub-type AWWA flanges?

Ring-type flanges are versatile for connecting components, while hub-type flanges serve specific sealing or closing purposes in water systems.

Do AWWA flanges have specific dimensional tolerances to ensure compatibility?

Yes, AWWA flanges adhere to specific dimensional tolerances to ensure they fit properly in water systems.

Can AWWA flanges accommodate insulators?

For larger AWWA flanges, bolt holes may be over-drilled to accommodate insulators or facilitate alignment with mating flanges.

What is the purpose of protective coatings applied to AWWA flanges?

Protective coatings enhance AWWA flange durability by providing resistance against corrosion and environmental factors.

How are AWWA flanges marked for identification and traceability?

AWWA flanges are steel-stamped with essential information, including the trademark, size, class, material designation, and material heat number.

Conclusion

In summary, AWWA flanges, though often working behind the scenes, are essential components in water utility systems and various light-duty applications. With their diverse pressure ratings, reliable welding compatibility, and stringent material standards, AWWA flanges silently ensure the efficient management of water resources and wastewater treatment. These unassuming components play a pivotal role in connecting pipes, valves, and equipment, making them indispensable in the world of water infrastructure.

For more in-depth information on AWWA flanges and their applications, visit https://www.texasflange.com/flange-specs/awwa/ to discover how they contribute to the effective management of water resources.