As a waterworks engineer, you know that the reliability of your systems is essential. AWWA flanges play a critical role in maintaining the reliability of your systems by providing a secure and leak-free connection between pipes and other components. It is important to choose flanges that meet the standards of the American Water Works Association (AWWA). The AWWA C207 standard specifies the requirements for AWWA flanges, including material, dimensions, pressure ratings, facing, and bolting.

Image Source: Texas Flange

Image Source: Texas Flange

Understanding AWWA C207 Steel Flanges

AWWA C207 steel flanges are pipe flanges that are specifically designed for use in waterworks applications. These flanges are often made from mild carbon steel or stainless steel and are commonly of the ring slip-on or blind disc style. AWWA C207 flanges are typically used in low-pressure applications, such as water distribution and transmission systems, wastewater treatment plants, and industrial piping systems. They are also commonly used in fire protection systems.

Image Source: Texas Flange

Types of AWWA C207 Steel Flanges

They are manufactured in accordance with the AWWA C207 standard, which covers the following types of flanges:

- Slip-on ring and hub-type flanges: Slip-on ring and hub-type flanges are the most common type of AWWA flange. They are easy to install and are suitable for a wide range of applications. Slip-on flanges are slipped over the end of a pipe and are secured with bolts and nuts.

- Blind flanges: Blind flanges are used to close off the end of a pipe or fitting. They are also commonly used to isolate sections of a piping system for maintenance or repair. Blind flanges are solid flanges with no bore. They are secured to the end of a pipe or fitting with bolts and nuts.

- Threaded iron flanges: Threaded iron flanges are used to connect pipes and fittings that have threaded ends. They are typically used in low-pressure applications. Threaded iron flanges are screwed onto the threaded ends of the pipes or fittings.

Specific Requirements For AWWA Flanges:

The AWWA C207 standard specifies the following requirements for AWWA flanges:

Material:

AWWA flanges must be made of steel that meets the following minimum requirements for physical and chemical properties:

- Sulfur: 0.05% maximum

- Phosphorus: 0.04% maximum

- Carbon: 0.29% maximum

- Tensile strength: 50,000 psi minimum

- Yield strength: 32,000 psi minimum

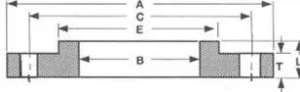

Dimensions:

Some of the common dimensions of AWWA C207 slip-on ring and hub-type flanges are:

- Size 4: OD 5.50 in, BCD 4.63 in, Thickness 0.75 in, Bolt Hole Diameter 0.62 in, Number of Bolts 8

- Size 6: OD 6.88 in, BCD 6.00 in, Thickness 0.88 in, Bolt Hole Diameter 0.75 in, Number of Bolts 12

- Size 8: OD 8.25 in, BCD 7.38 in, Thickness 1.00 in, Bolt Hole Diameter 0.88 in, Number of Bolts 16

- Size 10: OD 10.00 in, BCD 9.13 in, Thickness 1.13 in, Bolt Hole Diameter 1.00 in, Number of Bolts 20

- Size 12: OD 12.00 in, BCD 10.88 in, Thickness 1.25 in, Bolt Hole Diameter 1.13 in, Number of Bolts 24

Pressure ratings:

AWWA C207 steel flanges are available in a variety of pressure ratings, from Class 2B (150 psi) to Class 6F (300 psi). The pressure rating of a flange indicates the maximum pressure that it can withstand safely.

Facing:

AWWA C207 steel flanges are typically available with a flat face or a raised face. The facing that is chosen depends on the application and the requirements of the engineer.

- Flat-faced flanges are the most common type of facing for AWWA C207 flanges. They have a flat surface with no projection. Flat-faced flanges are typically used in low-pressure applications where a tight seal is not required.

- Raised-faced flanges have a raised rim on the facing surface. This raised rim helps to create a tight seal between the flanges. Raised-faced flanges are typically used in higher-pressure applications where a leak-tight seal is essential.

Bolting:

Bolting is an essential part of installing AWWA C207 steel flanges. The bolts must be properly sized and tightened to ensure a secure and leak-tight connection.

- Bolt Size: The size of the bolts depends on the size and pressure rating of the flange. The AWWA C207 standard specifies the minimum bolt size for each flange size and pressure rating.

- Bolt Tightening: The bolts must also be tightened to a specific torque. The AWWA C207 standard specifies the minimum torque for each flange size and pressure rating.

- Bolt Pattern: The bolt pattern for AWWA C207 flanges is also specified in the AWWA C207 standard. The bolt pattern is the arrangement of the bolt holes on the flange face.

Applications of AWWA C207 Flanges:

Here are some of the common applications of AWWA flanges:

- Water distribution and transmission systems

- Wastewater treatment plants

- Industrial piping systems

- Fire protection systems

- Irrigation systems

- Power plants

- Chemical plants

- Food processing plants

- Pharmaceutical plants

Advantages of AWWA C207

AWWA C207 steel flanges offer a number of advantages over other types of flanges for waterworks applications, including:

- Reliability: AWWA C207 flanges are manufactured to strict standards and are designed to perform reliably in demanding waterworks environments.

- Durability: AWWA C207 flanges are made of durable materials and are resistant to corrosion and other environmental factors.

- Versatility: AWWA C207 flanges are available in a variety of sizes, pressure ratings, and facings, making them suitable for a wide range of waterworks applications.

- Compatibility: AWWA C207 flanges are compatible with other waterworks components, such as pipes, valves, and fittings.

- Ease of installation: AWWA C207 flanges are relatively easy to install, even in confined spaces.

FAQ

Q1. What is the AWWA C207 standard, and why is it important for steel flanges?

The AWWA C207 standard is a set of guidelines established by the American Water Works Association to ensure the quality and performance of steel flanges used in critical systems. It’s vital to guarantee that these flanges meet specific requirements for reliability and compliance.

Q2. What are the key material requirements for AWWA C207 steel flanges?

AWWA C207 specifies stringent material requirements, including limits on sulfur, phosphorus, carbon content, and minimum tensile and yield strength. These requirements are crucial for the flange’s ability to withstand various conditions.

Q3. How do dimensional tolerances affect the functionality of AWWA C207 steel flanges?

Dimensional tolerances ensure that steel flanges fit perfectly and securely with other components. Deviations from these tolerances can result in improper fit, potentially leading to leaks and disruptions in your system.

Q4. How can I determine the right pressure rating for my AWWA C207 steel flanges?

The selection of the right pressure rating depends on the specific application and the maximum pressure your system will experience. AWWA C207 provides a range of pressure ratings to accommodate different needs.

Q5. What are the main facing options for AWWA C207 steel flanges, and how do I choose the right one?

AWWA C207 offers facing options such as raised face and ring joint face. The choice depends on factors like the type of gasket and sealing required for your specific application.

Q6. What best practices should I follow when bolting AWWA C207 steel flanges for reliable connections?

Proper bolting practices are essential for secure and long-lasting connections. This includes using the correct size and type of bolts and nuts, ensuring even torque, and following established procedures for bolting.

Conclusion

In conclusion, AWWA C207 steel flanges are a type of flange that is specifically designed for use in waterworks applications. They offer a number of advantages over other types of flanges, including reliability, durability, versatility, compatibility, and ease of installation. Additionally, AWWA C207 flanges offer superior sealing performance, resistance to corrosion and wear, and a wide range of operating temperatures. Overall, AWWA C207 steel flanges are a good choice for waterworks applications.

To find more in-depth information, resources, and expert guidance on AWWA C207 flanges, visit the website: https://www.texasflange.com/